Choose the Right Florida Retaining Wall: Redi-Rock, Novum Wall, or Dry Cast SRW

Not all retaining wall systems are built to handle the challenges of Florida and South Georgia. Dry cast segmental retaining wall (SRW) products are common in the market, but their performance can vary in our region’s demanding conditions. If you’re evaluating Redi-Rock or Novum Wall against traditional dry cast SRW systems, understanding the key differences will help you choose the right retaining wall solution for long-term success.

The True Story

Short on time? Here are this article’s key takeaways…

Our side-by-side comparison shows how wet cast retaining wall systems like Redi-Rock and Novum Wall stack up against dry cast SRW walls.

Redi-Rock and Novum Wall systems offer engineered designs that can handle Florida’s complex (and wet) site conditions, often offering quicker installations and long-lasting solutions.

While typically less expensive to produce, dry cast SRW systems generally are smaller and more porous, increasing labor and maintenance demands.

For long-term value, Redi-Rock and Novum Wall are the best choices for return on investment with lower lifecycle costs, machine-set construction, and proven results for projects of varying complexity.

| Category | Redi-Rock | Novum Wall | Dry Cast SRW Walls |

|---|---|---|---|

| Design Flexibility | More than 100 retaining wall block types. Can be used for multiple wall types. Can build walls up to 50 ft tall (depending on site). | More than a dozen block types. Can be used for multiple wall types. Can build walls exceeding 25 ft tall (depending on site). | Limited block shapes and sizes. Gravity walls are typically limited to 4 ft. SRW mechanically stabilized earth (MSE) walls can be constructed to tall heights, with documented cases exceeding 50 ft. |

| Installation | Installations with time-saving, small crew (2-3) using excavators. | Installations are efficient, small crew (2-3) with equipment like skid-steers and mini-excavators. | Mainly hand-placed blocks, requiring crews to complete all lifting and positioning. May require additional cutting and fitting blocks on-site. |

| Site Suitability | Excellent for when utilities or property lines are nearby, box culvert bridge abutments, and high-profile projects where excavation is limited. | Ideal for small, tough-to-access areas, high-visibility projects demanding a smaller scale and tight project boundaries. | Ideal for dry sites where machinery access is limited and projects are fairly small in scale. |

| Durability | Produced in quality-controlled conditions, resistant to water damage. | Produced in controlled conditions, resistant to water damage. | More porous composition, allowing for water intrusion, which can damage the wall. |

| Appearance | Deeply textured, stone-like, region-specific color options. | Deeply textured, stone-like, region-specific color options. | Limited depth and detail of texture on finished blocks. |

| Design Support | Design and engineering tools, in-house engineering support. | Design and engineering tools, in-house engineering support. | Limited to general product guidance. Detailed design input, structural analysis, and site-specific engineering are usually handled by third-party consultants rather than the product manufacturer. |

| Cost Considerations | Higher initial materials investment, lower installation and lifecycle costs. | Higher initial materials investment, lower installation and lifecycle costs. | More economical compared to large-scale wet cast products, but maintenance and installation costs can be higher. |

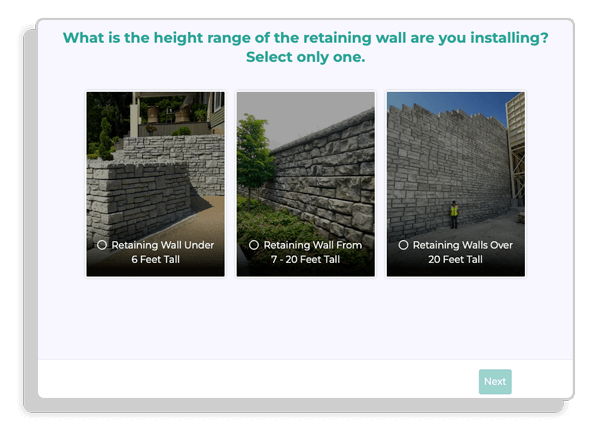

Answer six quick questions to see your retaining wall’s material cost

Use your estimate to budget and move forward with installation planning.

Find the right solution: Discover which wall system best fits your project’s size and site needs.

Connect with experts: Get a follow-up from Truemont to refine details and finalize your quote.

Design Flexibility: What Works—and What Doesn’t—for Florida Projects

Redi-Rock. Built to perform under pressure—designed with adaptability, strength, and long-term durability. Redi-Rock’s comprehensive library of precast modular blocks makes it easy to design and construct gravity walls, reinforced (MSE) walls, freestanding walls, and hybrid solutions. With non-corrosive components and proven performance in challenging water environments, Redi-Rock is a smart choice for large-scale retaining wall projects, seawalls, and other waterfront applications where durability matters most.

Novum Wall. Delivers site-specific solutions using durable wet cast concrete, just like its larger counterpart, Redi-Rock. Designed for flexibility, Novum Wall supports gravity, reinforced (MSE), freestanding, and hybrid wall systems. It’s also a strong fit for marine environments, including canal edges and certain bridge applications, where long-lasting performance is essential.

Dry Cast SRW. Gravity wall heights are limited, typically requiring reinforcement to reach the heights Redi-Rock can achieve without it. Shape variety is also restricted, with few options for half blocks, corners, or variable setbacks. And because dry cast concrete is more porous, these blocks are not well-suited for water exposure or marine environments.

Installation: Choose your Speed

Redi-Rock & Novum Wall. The Redi-Rock and Novum Wall block catalogs feature larger solid and hollow core block options than smaller SRW products. The larger blocks cover more area per block, speeding up the installation process and reducing labor costs. Redi-Rock’s large blocks are ideal for accelerating construction on big infrastructure projects, while Novum Wall’s smaller units offer a cost-effective solution for tighter spaces and constrained job sites. Both are machine-set systems, which can be installed with small crews. Dry Cast SRW. These systems use smaller blocks with limited shape variety. Contractors are often required to modify blocks on-site to fit project needs. Installation is typically done by hand, with crews responsible for lifting and placing each unit—leading to a more labor-intensive process and potentially higher labor costs.

Site Suitability: Right Wall, Right Place

Redi-Rock. With durable wet cast concrete and a modular design, Redi-Rock is well-suited for walls in environments requiring strength and storm resilience. As an FDOT-approved system, it’s a reliable choice for public and private projects—offering dependable performance without compromising aesthetics. Novum Wall. Optimal for retaining wall projects in areas with limited access, or for residential projects, parks, and HOA upgrades. Its lighter weight and smaller footprint make it easier to maneuver in tight spaces, all while delivering the structural capacity to build tall gravity walls with minimal equipment constraints and a polished, professional finish. Dry Cast SRW. Dry cast blocks exhibit poor performance in water conditions because of their higher porosity, resulting in increased water absorption. This permeability can undermine the block's integrity over time, leading to possible deterioration or weakening of the structure. It may necessitate additional maintenance and sealing to safeguard against water intrusion.

Durability: Long-Term Matters

Redi-Rock & Novum Wall. Manufactured in controlled environments, ensuring consistent quality and uncompromised concrete at installation. Redi-Rock and Novum Wall feature modular designs and patented interlocking systems that allow walls to adapt seamlessly to a site’s natural contours. Both systems are engineered to perform under pressure—easily supporting live load demands. Dry Cast SRW. These blocks cure quickly and can be installed shortly after production, which can help keep schedules moving. However, dry cast concrete is more porous and less dense than wet cast alternatives—making it less durable in consistently wet or saturated conditions. For regions like Florida and South Georgia, where high moisture, heavy rains, and stormwater exposure are common, dry cast systems may not offer the long-term performance required.

Appearance: Stone Looks, Real Performance

Redi-Rock & Novum Wall. Feature rich, natural-looking textures molded from real stone, adding visual impact to any project. Redi-Rock brings bold aesthetic appeal to large-scale applications like highways, bridges, parking structures, and waterfront walls. Novum Wall offers a refined finish ideal for smaller, high-visibility spaces such as residential developments, golf courses, or private properties. Both systems can be enhanced with custom color treatments using post-installation staining techniques. Dry Cast SRW. Because dry cast blocks are formed through high-pressure compression, the resulting texture is typically shallow and lacks definition. This manufacturing method limits the ability to capture deep, realistic stone details, often leading to a flatter, more uniform appearance on finished walls.

Lifetime Value: Built-In ROI

Redi-Rock & Novum Wall. While material costs for both precast systems may be somewhat higher upfront, their fast installation, long-term durability, and minimal maintenance often result in greater overall value across the project's life. Dry Cast SRW. While rapid production can make these blocks more affordable upfront, installation inefficiencies often drive up labor costs. The limited variety of sizes and shapes may require additional on-site cutting, slowing progress. Some systems also rely on alignment pins, bars, or other connectors, which can further extend installation time.

Looking for pricing? Use our wall budget estimation tool to generate a cost snapshot for Redi-Rock or Novum Wall retaining walls.

The Verdict: Which Wall is Right for your Florida Project?

Choose Redi-Rock if you:

- Need a fast, scalable solution for public infrastructure or commercial developments

- Are working in wet or flood-prone conditions where space is limited and tall, geogrid-free gravity walls are preferred over reinforced systems

- Prioritize long-term performance, structural reliability, and a natural stone appearance

Choose Novum Wall if you:

- Have limited access on-site, smaller crews, or need a quicker installation process

- Want a solution that offers aesthetic appeal, dependable strength, and cost efficiency

- Are designing for compact areas such as residential neighborhoods, parks, or shared community spaces

Choose Dry Cast SRW if you:

- Are building small-scale walls in dry, well-drained environments

- Have a tight budget and can manage more on-site labor and installation time

- Don’t require high-end textures or marine-grade durability for your project

Get an Instant Estimate

Answer six quick questions to see your retaining wall’s material cost