Jax One Riverside Development Chooses Redi-Rock over Cast-In-Place

Owner: Whole Foods Engineer/Designer: Devlin Engineering Location: Jacksonville, Florida Year Built: 2025 Wall Size: 831 sq ft Wall Type: Gravity Texture: Ledgestone

THE CHALLENGE

Sometimes the smallest components can make the difference in the most significant development projects. For Jacksonville’s $250 million One Riverside development, an 831 sq ft Redi-Rock gravity retaining wall went up in under a week, delivering the critical infrastructure needed to keep this high-profile project on schedule.

The Brooklyn neighborhood project includes 271 multi-family units, over 40,000 sq ft of retail space, and a 7-deck parking garage. The parking structure was largely complete, and work was underway on the adjacent retail space when developers determined that a retaining wall was necessary to continue the construction of the building that would house a Whole Foods Market.

The selected retaining wall solution needed to satisfy several requirements, including:

- Quick, efficient installation to minimize any impact on the overall project’s schedule

- Construction within a difficult-to-access footprint that didn’t offer space for installation of a mechanically stabilized earth (MSE) wall

- High-end, natural stone-like looks befitting a luxury riverside reclamation project

The proposed 13.5 ft tall wall needed to be installed quickly, constructed on a tight site, and look good. But most importantly, the selected wall system had to be strong enough to support the large equipment necessary to continue construction of the Whole Foods Market building.

THE SOLUTION

As developers considered their wall options, they faced several significant challenges threatening the larger project's timely completion. Initial plans called for the construction of a cast-in-place wall. The cast-in-place concept was quickly scrapped when it became clear that the time required for forming, pouring, and curing the cast-in-place wall would disrupt the One Riverside project’s overall schedule.

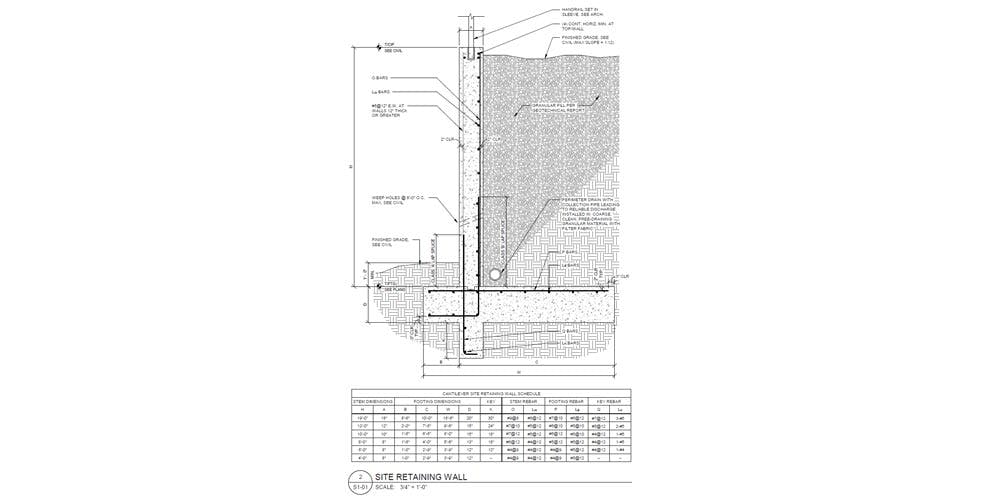

The initially proposed cast-in-place retaining wall detail that was abandoned when it was determined to require too much time to complete. Choosing Redi-Rock over cast-in-place doesn’t just save time; contractors claim overall wall project savings of as much as 40 percent on some projects.

The initially proposed cast-in-place retaining wall detail that was abandoned when it was determined to require too much time to complete. Choosing Redi-Rock over cast-in-place doesn’t just save time; contractors claim overall wall project savings of as much as 40 percent on some projects.

Developers chose a Redi-Rock gravity retaining wall supplied by nearby producer Truemont Materials. The Redi-Rock precast modular block (PMB) retaining wall system is trusted by thousands of engineers worldwide to support vital public and private infrastructure projects. The FDOT-approved resilient retaining wall system is particularly effective in Florida since it can be installed despite higher water tables, and its massive precast modular blocks are engineered to withstand tidal fluctuations and flooding, storm surges, and hurricane-force winds.

Redi-Rock offered several advantages critical to the success of the One Riverside project:

- Built in a Tight Spot. A small project site footprint didn’t allow space for reinforcement, including geogrid.

- Lightning Fast Installation. The wall was built in less than a week with a small crew and minimal equipment.

- Serious Live-Load Support. Redi-Rock’s massive but manageable size enabled 30,000+ ton loaded concrete pump trucks to operate off the surface, supported by the wall.

- Lean Logistics. Produced and delivered on demand, blocks were provided when needed, keeping the project site orderly.

- Natural Stone Aesthetics. The deeply grooved Ledgestone texture beautifully replicated the appearance of high-end stacked, natural stone.

These benefits weren’t just theoretical. They proved essential once construction began.

THE PROJECT

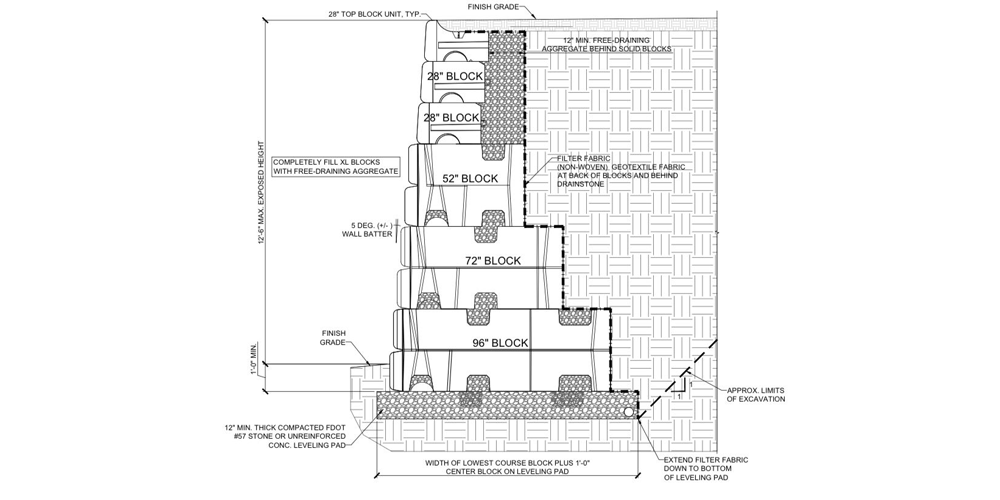

Knowing the retaining wall would have to support significant live loads from the moment it was completed, project engineers selected Redi-Rock’s XL Hollow Core blocks to comprise the ever-important lower three courses (levels) of the retaining wall. XL Hollow Core blocks are available in three depths – 52, 72, and 96 in – and deliver the strength of a gravity wall at greater heights with fewer materials, faster installation, and reduced excavation requirements. XL Hollow Core blocks are also compatible with other components of the Redi-Rock system, extending flexibility to engineers tasked with designing walls for challenging sites like One Riverside. The One Riverside wall design called for all three sizes of XL Hollow Core blocks, with Redi-Rock’s 28 in Middle and Top blocks comprising the upper three courses.

Cross-section of the final Redi-Rock wall demonstrating the advantages of the Redi-Rock system.

Cross-section of the final Redi-Rock wall demonstrating the advantages of the Redi-Rock system.

The wall was erected following the construction of a 12 in thick leveling pad. The 96 in Hollow Core blocks formed the first two courses, followed by two courses each of 72 and 52 in XL Hollow Cores. As the XL Hollow Core courses were installed, crews filled their cavities with aggregate, adding mass to the gravity wall and essential drainage capabilities to its lower courses. Two courses of 28 in Middle blocks were placed next, with the top of the wall finished with 28 in Top blocks.

The installation of the 831 sq ft wall took less than a week, ensuring the overall project remained on schedule.

THE OUTCOME

The One Riverside retaining wall met every demand of this high-profile project, delivering the strength, speed, and aesthetics that cast-in-place simply cannot. By leveraging Redi-Rock XL Hollow Core blocks for the base and seamlessly integrating standard Middle and Top blocks above, engineers achieved a design that maximized stability without sacrificing valuable space. The wall’s ability to support heavy construction equipment kept the larger project on schedule, while its deep natural stone texture elevated the look of the development’s streetscape.

In just a few days, what could have been a costly delay was transformed into a durable, visually striking retaining solution that will continue to support this vital area of the One Riverside community into the next century.

Products Featured

52 in (1320 mm) XL Block 72 in (1830 mm) XL Block 96 in (2440 mm) XL Block 28 in (711 mm) Middle Block 28 in (711 mm) Top Block